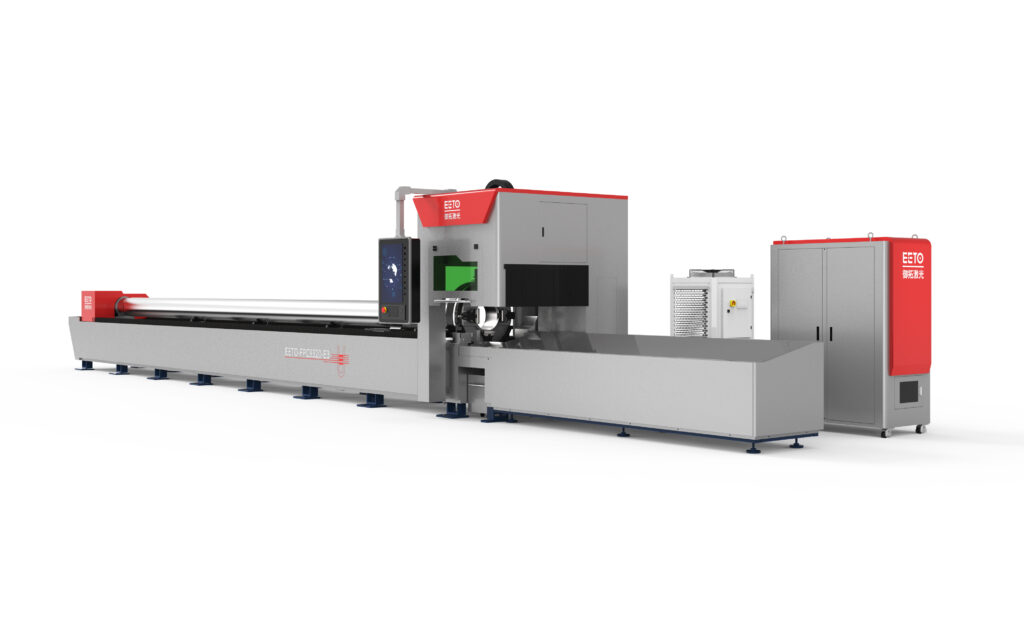

CUTTING OF METAL PIPES AND PROFILES - Tube laser

Currently, the average labour intensity of procurement work in mechanical engineering is 40-45% of the total labour intensity of the production of mechanical engineering products. The main trend in the development of procurement production is to reduce the complexity of mechanical processing in the manufacture of machine parts by increasing the accuracy of their shape and size.

The company Tootlus OÜ offers a range of services for cutting long blanks from profiles of various types and pipes. The cutting technology is selected based on the requirements for the cutting edge, the shape of the types, cutting holes of any most complex shapes, taking into account the specifics of metalworking. Cutting is carried out in full accordance with the customer’s drawings on high-precision equipment, which allows minimizing the percentage of waste and optimizing the cutting process. The tube laser makes it possible to ensure the accuracy of processing within +/- 0.3 mm.