BENDING OF METAL PIPES AND PROFILES

If you need high-quality and prompt bending of pipes, we use modern equipment and offer our customers the bending of round and profile pipes, of round and flat material by the winding method, where defects and changes in geometry depending on the bending option are excluded.

Pipe bending, unlike welding, looks quite neat. This process increases the profitability of our company’s production as well as reduces the painstaking manufacturing of products.

The very method of winding, its technology is a very precise bending of steel, stainless, aluminum and other materials. We offer bending of both thin-walled and thick-walled pipes and profiles, bending with fixed and variable radius.

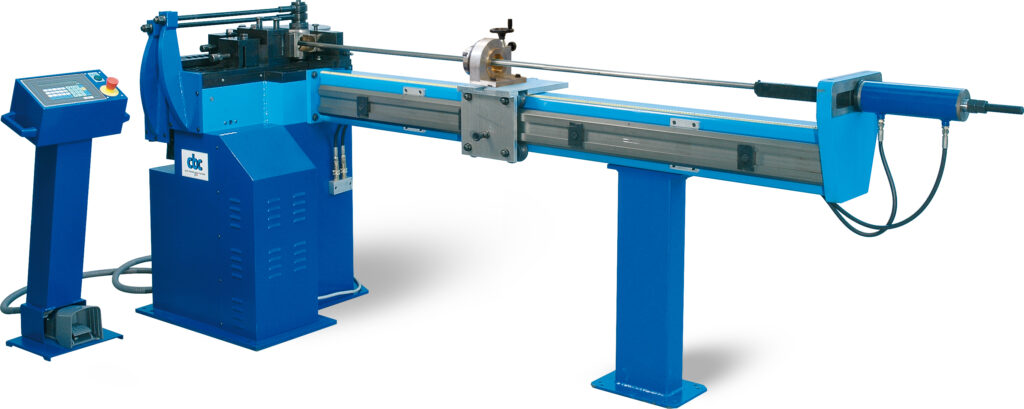

We know a lot about high-quality pipes, as we ourselves use this technology in the manufacture of stair and balcony fences, as well as in various grilles and gates. Due to the operation of high-tech automatic pipe bending machines, we spend a minimum of time on bending. Thus, our customers receive finished products with a high-precision bending angle and of excellent quality.